当前位置:网站首页>Baidu PaddlePaddle easydl helps manufacturing enterprises with intelligent transformation

Baidu PaddlePaddle easydl helps manufacturing enterprises with intelligent transformation

2022-07-21 01:19:00 【Paddlepaddle】

As industrial 4.0 Coming of age , How to use the sharp sword of artificial intelligence , Realize the transformation and upgrading of traditional production methods , Standing at the tide of a new round of industrial revolution , It has become a problem that every industrial manufacturing enterprise has to think about . Industry has a lot of data accumulation , Industrial production 、 Quality testing 、 Management and other links are continuing 、 A lot of 、 Quickly generate data , It is the blue ocean of artificial intelligence applications . The present , Represented by machine vision AI technology , Is being widely used in 3C Electronics 、 Food manufacturing 、 Automobile parts manufacturing and other fields , Including defect detection 、 Production environment, safety and other functions ,AI In the process of industrial intelligent transformation, high hopes are also placed on .

In the field of industrial quality inspection AI application

Manufacturing is inseparable from quality inspection . The products we are looking for , They all pass through the industrial quality inspection link before they leave the factory smoothly .

There is a strong demand for quality inspection in all walks of life

Quality inspection requires high precision , Accounting for% of the total labor cost of the factory 40%. for instance , Bearing defect detection target in industrial quality inspection , It could be a small scratch , Or it could be a small gap . In this case , Defective visual senses are not intuitive . In the whole process of human testing , It takes a lot of time 、 High manpower investment . The efficiency of quality inspection directly affects the production and delivery efficiency of enterprises . therefore , The intelligent empowerment of industrial quality inspection has become a cost saving , The inevitable trend of increasing production capacity .

Industrial quality inspection direction , Through the evolution of three processes :

You can see from the above picture that , In the deep learning stage , It can gradually solve the problem of complex defect shape 、 Goals with complex environments , A wider range of problems can be solved , More scenes covered . But the threshold of deep learning is high , stay AI The development phase , Higher requirements for raw data , The requirements for developers are also higher .

that , Is there a simple way to get started and ensure efficient quality inspection ?

Car parts AI Quality inspection pain and difficulty

The current case enterprise comes from the solution provider in the direction of industrial bearing quality inspection —— Wesken , Have deep business scenarios and technical accumulation in the direction of bearing quality inspection ; But in AI Algorithm field , Lack of deep enough technical precipitation . In the process of intelligent empowerment , Defect detection problems encountered by enterprises , Mainly including internal material inspection 、 Size / Shape and position detection and appearance defect detection .

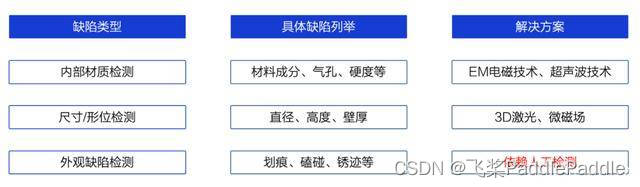

Defect types and solutions commonly used by enterprises

Internal material inspection : Including material composition 、 Porosity and hardness test , At present, the main technology used is EM Electromagnetic technology and ultrasonic technology to do relevant testing ;

Size / Shape and position detection : For example, check the diameter of the bearing 、 Whether the height and wall thickness meet the requirements , The current is through 3D Laser and micro magnetic field technology ;

Appearance defect detection : Including scratches on the surface 、 Bump 、 Internal rust . Traditional machine vision cannot solve the problem of relative irregularity for the time being , Including defect location , Usually rely on manual detection .

The enterprise also tried to set up an algorithm team to do AI Development , Solve the problem of intelligent detection , But the algorithmic personnel needed to form an algorithmic team 、 The time cost of investing in the research process 、AI The cost of machines such as servers that need to be invested in training is accumulated , It is estimated to reach a million . The core appeal of the enterprise is to reduce the investment in the early exploration stage , utilize AI Enable appearance defect detection scenario , So as to improve the efficiency of the overall quality inspection link , The above is the demand background of the enterprise users .

As a solution provider of deep ploughing bearing quality inspection for many years , In the process of intelligent transformation, they encountered the following main problems :

First , How to reduce the cost investment in the business exploration stage ?

second , How to accurately mark defects , So as to provide high-quality training data ?

Third , How to collect data of various defects , Make up for the pain point of less defective samples ?

Fourth , How to adapt various hardware , Simple and efficient deployment ? How to ensure prediction efficiency ?

So how does the enterprise user pass Flying propeller EasyDL Solve the problem one by one , And get high returns ?

be based on Flying propeller EasyDL Create a finished bearing visual inspection solution

First , The defects of automobile bearing are analyzed , So as to preliminarily determine the need for application Flying propeller EasyDL What kind of model .

Combined with defect characteristics , Select the applicable task type

Determine the use based on defect analysis Flying propeller EasyDL Object detection and image segmentation model . Next, start data preparation around the defect detection of the end face → model training → Model deployment .

Data preparation

The defect to be tested is too small , Marking is difficult , At the same time, mark a large number , High labor costs . stay Flying propeller EasyDL On the annotation interface , Provide many zoom in or zoom out tools for targets with small defects , You can zoom as needed for accurate annotation . Here's the picture :

In the face of a large amount of data , Intelligent annotation function can be adopted . Start smart annotation after a few annotations , It can intelligently analyze the marked pictures , Then mark the remaining pictures with one click . Take this enterprise as an example ,200 It takes time to mark the picture manually 3 Hours , The remaining 600 Smart tagging of a picture takes only 1 Hours .

model training

The sample size of some defects is small , How to improve data utilization ? through Flying propeller EasyDL Data enhancements , One picture can be derived from more than one picture , Improve data utilization . meanwhile , Through the automatic hyper parameter search strategy , The utilization of data training in relatively complex scenes , At the same time, the optimal parameter combination based on this scenario can be produced , Achieve higher model accuracy . If the target detector is too small , You can choose a small target detection algorithm . The enterprise in this scenario , choice 800 A defect picture , No code training gives an accuracy rate of 90% Available models .

Model deployment

The problem encountered by enterprises is that the overall prediction delay will directly affect the quality inspection efficiency . Use EasyDL Provided model acceleration function , Compress the model volume without loss of accuracy , Reduce prediction delay . The enterprise compresses the model and deploys it in T4 Server , Single picture prediction can be made in 100ms Finish in .

meanwhile , Flying propeller EasyDL The output model hardware adapts widely , One click export of the platform to adapt to the mainstream hardware SDK The package completes the model deployment . For businesses , There is no need to do additional hardware adaptation , Significant savings in work costs .

Final , The enterprise built a platform based on Flying propeller EasyDL Visual inspection solution for finished bearings . be based on Flying propeller EasyDL Machine learning detection algorithm , Use the industrial camera to take pictures of the bearings on the production line , The geometric parameters of the bearing are obtained by the sensor and drawn into an image , The server at the production site carries out image classification and detection , Judge whether the appearance quality of the bearing meets the requirements , It can detect the scratch of the bearing 、 Bruise 、 Bruise 、 Chipping 、 Rust and other defects .

This article is shared in Blog “ Flying propeller PaddlePaddle”(CSDN).

If there is any infringement , Please contact the [email protected] Delete .

Participation of this paper “OSC Source creation plan ”, You are welcome to join us , share .

边栏推荐

猜你喜欢

IDEA:Lambda expression are not supported at language level ‘5‘

Classes et objets (en haut)

VMware startup error: exception 0xc00000005 and windwos11 have no Hyper-V solution

Arduino reads the sensor data and saves it in Excel

【2022国赛模拟】相似序列问题——DFA(DP套DP)

xss漏洞的一些思考

VMware 启动报错:Exception 0xc0000005和windwos11没有Hyper-V的解决方法

NVIDIA NX usage notes

STM32学习---SPI

![[leetcode] 12. Arbre binaire équilibré · Arbre binaire équilibré](/img/4a/e52117f07cbb34f375ab096ffa7ca4.png)

[leetcode] 12. Arbre binaire équilibré · Arbre binaire équilibré

随机推荐

uview錶單,身份證,鍵盤,實時驗證

[pyGame] the classic boss of soul duel is back. Are you ready to defeat them again? (source code attached)

Operation of variables in MySQL

QT_ Embedded main interface addition and switching effect

DNS domain name resolution

Glue terraform ecology to kubernetes world

机械制造企业,如何借助ERP系统解决仓库管理难题?

电气成套设备制造企业项目管理难点及解决方案

进程间的通信方式

虚拟机中docker安装mysql远程无法访问解决方法

Survey of network intrusion detection based on deep learning

Animation animation in unity is played backwards and forwards

[solve ax=b]

音视频入门——H.264编码(宏块+片+帧)浅析

VMware startup error: exception 0xc00000005 and windwos11 have no Hyper-V solution

Unity Shader着色器学习(二)

What is the difference between zero trust and SASE? The answer is not really important

Classes and objects (top)

Question 124 of Li Kou: maximum path sum in binary tree

Qt:Could not find qmake spec ‘default’.Error while parsing file xxx.pro. Giving up